Computational Fluid Dynamics Laboratory

In order to tackle challenging multiphase flow problems, the NUEM group largely relies on the support of Computational Fluid Dynamics (CFD). This requires specialized software, computational power, experienced personnel and, in general, a good infrastructure. Over its existence, the NUEM organization has received massive investments to consolidate a CFD group capable of conducting cutting-edge projects on multiphase flows.

Responsible Researcher

Henrique Stel de Azevedo, Dr. (stel.henrique@gmail.com)

On the hardware side, NUEM’s infrastructure consist of a set of constantly updated, fast computers equipped with top-quality components optimized for CFD. Besides dozens of units with 7th and 8th generation Intel® processors for general purpose simulations, NUEM has today a handful of devices equipped with high-end CPUs, including Intel®’s i9 and AMD® Ryzen Threadripper processors. On top of all that, NUEM owns an expandable, 188-core, HPC Cluster with 960 GB of RAM, providing up to 18.4-teraflop processing capability, which is used for very computationally demanding problems.

As of specialized software, NUEM counts with a full HPC license of the ANSYS ® CFD package, consisting of the market-leading ANSYS ® CFX ® and ANSYS ® Fluent ® programs, the ANSYS ® ICEMTM, ANSYS® Meshing®, and ANSYS® TurboGrid® mesh generating modules, and many other programs of the ANSYS® CFD ecosystem that together create a strong CFD workflow tool. NUEM is also licensed by Kongsberg® with their LedaFlow® software for specific-purpose simulations of processes in the oil industry, as well as other software used for thermodynamics projects, including the commercial MultiFlash®, EES® and NIST-REFPROP® packages.

This physical and computational capability is well distributed in the NUEM building in Curitiba, Brazil, internally connected through a fast logical network. However, all this capability is entirely accessible through remote VPN, which is very helpful in many situations where simulations should be handled from outside of the central headquarters. This turned out to be a key advantage in the COVID-19 pandemic, allowing efficient and, most importantly, safe work from home for as long as social distancing remains necessary.

Finally, on the human resource side, NUEM has consolidated over the years an experienced CFD team to help students and researchers in every aspect of a serious CFD workflow, which includes IT support, problem conceptualization and preparation, mesh generation, post-processing, results interpretation, and communication to the scientific community.

Capability

Class-leading CFD Tools: Full HPC license of the ANSYS® CFD® solutions, the market-leading package for CFD workflows, as well Kongsberg® LedaFlow®, and many in-house, dedicated codes developed in OpenFOAM® and other general-purpose programming languages.

Solid CFD Team: Strong research team dedicated to problem preparation, model implementation, and flow analysis of CFD projects.

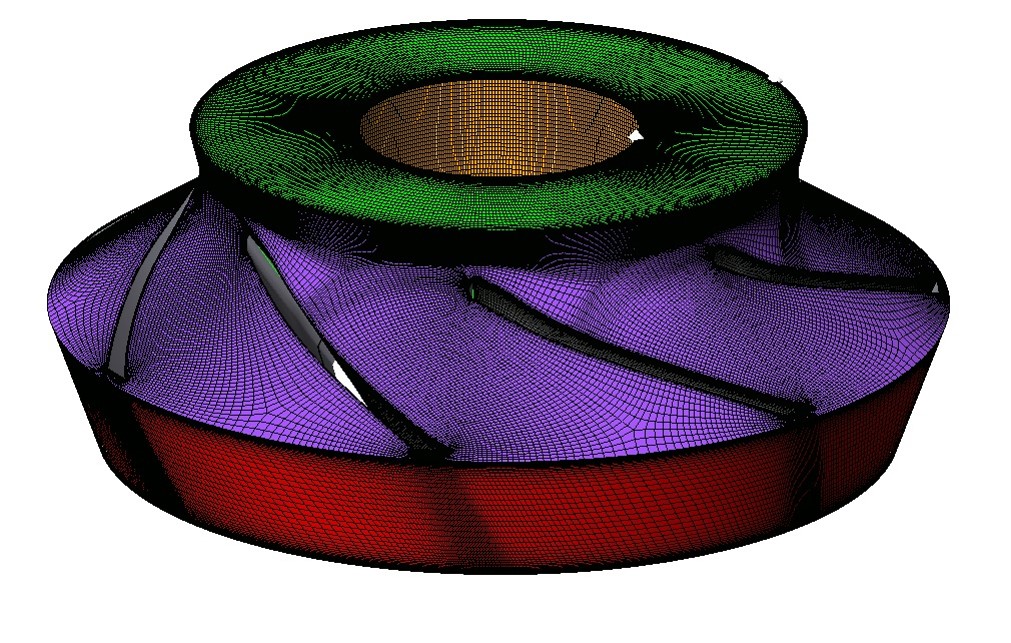

Advanced numerical mesh generation: Large experience with high-quality mesh generation, fundamental to cutting-edge CFD solutions.

Dedicated supporting data: Close support of NUEM’s experimental works providing necessary data for input and model validation.

Reliable thermodynamic inputs: Availability of celebrated software providing high-quality thermodynamic inputs, including the commercial MultiFlash®, EES® and NIST-REFPROP® packages, as well as in-house, carefully validated codes.

Comprehensive post-processing: Consolidated practices to extract the most out of the CFD results through careful post-processing, using both the ANSYS ® modules and external software, including Tecplot ®, ParaView, MATLAB ® and PythonTM.

Serious computational power: State-of-the-art, and constantly updated, computational capability, including a dedicated, 188-core, 18.4-teraflop HPC Cluster, to tackle a wide range of CFD problems.

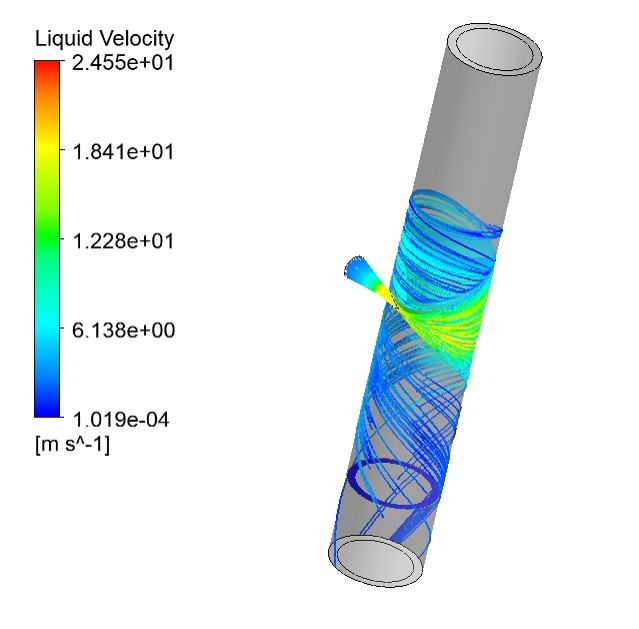

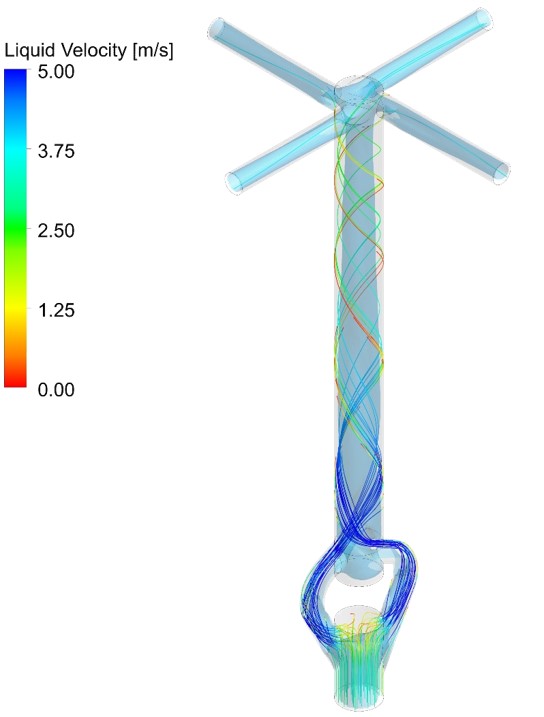

Experimental and CFD – Gas-liquid flows in centrifugal pumps

High quality mesh generation in complex geometries

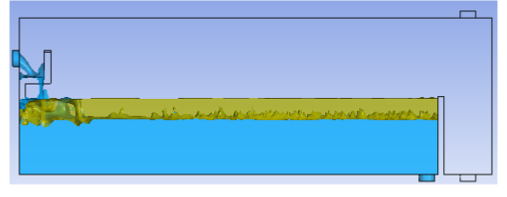

Design and analysis of separation systems